Preparing Your Industrial Warehouse for Seasonal Changes in Australia

Understanding Seasonal Changes in Australia

Australia's diverse climate means that industrial warehouses must be prepared for a variety of weather conditions throughout the year. From sweltering summers to chilly winters, each season poses unique challenges that can impact the efficiency and safety of warehouse operations. Understanding these seasonal changes and their potential effects on your warehouse is the first step in ensuring seamless operations all year round.

Spring: Embrace Maintenance Opportunities

Spring is an ideal time to conduct maintenance activities in your warehouse. As the weather warms up, it's crucial to inspect the roofing and gutters for any damage caused by winter storms. Ensure that ventilation systems are working efficiently to prepare for the upcoming summer heat. Regular maintenance during spring can prevent costly repairs and downtime later in the year.

Additionally, spring is a good time to review your inventory management processes. With milder weather conditions, it's easier to reorganize stock and perform thorough inventory checks. Streamlining these processes now can lead to more efficient operations during busier periods.

Summer: Combat Heat and Humidity

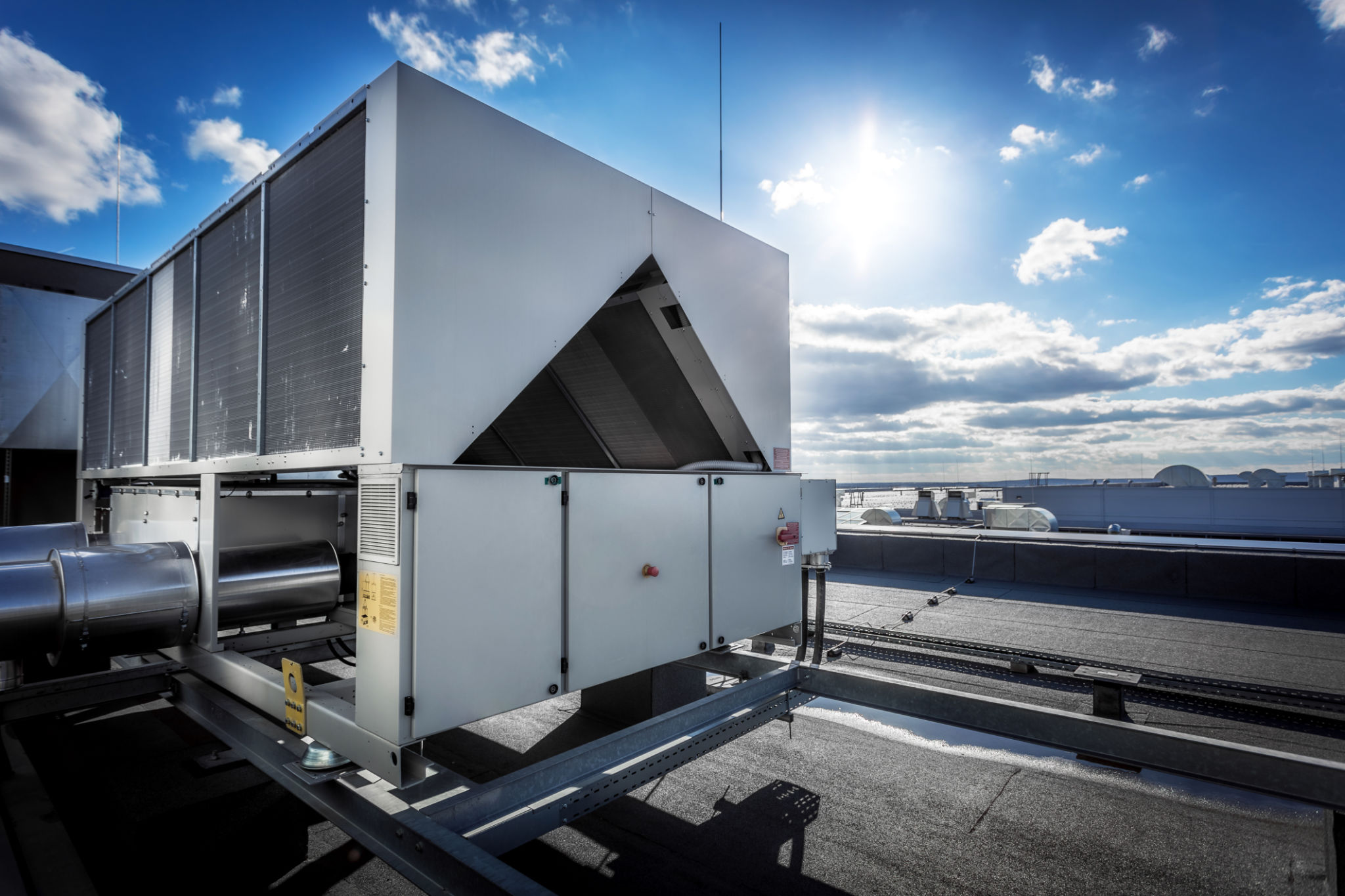

Summer in Australia can bring intense heat and humidity, which can affect both your staff and stored goods. It's important to ensure that your warehouse is well-ventilated and equipped with adequate cooling systems to maintain a safe working environment. Consider investing in energy-efficient cooling solutions to reduce costs.

For temperature-sensitive products, maintaining appropriate storage conditions is vital to prevent spoilage or damage. Implementing smart technology, such as temperature and humidity sensors, can help monitor conditions in real-time, ensuring immediate action if necessary.

Autumn: Optimize Energy Efficiency

As temperatures begin to cool down in autumn, it's a great time to focus on optimizing energy efficiency within your warehouse. Conduct an energy audit to identify areas where energy consumption can be reduced. Simple actions like sealing windows and doors, using energy-efficient lighting, and optimizing heating systems can lead to significant savings.

Moreover, autumn is a good time to assess your warehouse's insulation. Proper insulation can help maintain consistent temperatures, reducing reliance on heating and cooling systems and ultimately lowering operational costs.

Winter: Ensure Safety and Warmth

Winter in Australia can bring cooler temperatures and increased rainfall, making it essential to ensure your warehouse is safe and warm. Check that heating systems are functioning efficiently and address any leaks or drafts that could compromise interior temperatures.

Safety is also a priority during winter months, as wet conditions can lead to slippery floors. Implementing non-slip flooring solutions and ensuring adequate drainage can help maintain a safe environment for staff and equipment.

Year-Round Considerations

Beyond seasonal preparations, there are several year-round considerations for maintaining an efficient warehouse. Regular staff training on safety protocols, equipment handling, and emergency procedures is crucial for preventing accidents and ensuring smooth operations regardless of the season.

Additionally, leveraging technology like inventory management software and automated systems can enhance productivity and streamline processes throughout the year. These tools provide valuable insights into inventory levels, operational efficiency, and potential areas for improvement.

Conclusion

Preparing your industrial warehouse for seasonal changes in Australia involves proactive planning and regular maintenance. By understanding the unique challenges presented by each season and taking appropriate measures, you can ensure your warehouse operates efficiently and safely all year round. Embrace each seasonal opportunity to enhance operations, reduce costs, and maintain a productive work environment for your team.